Utilizing our cutting-edge manufacturing video analytics system, AIVIS, let’s revolutionize your labor-intensive and monotonous tasks into smart, AI-driven processes.

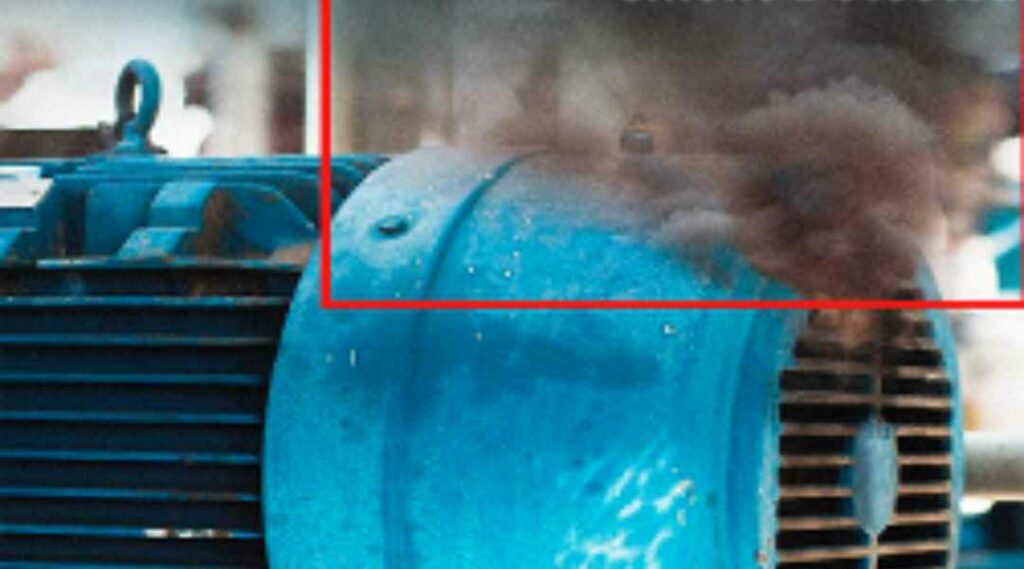

While manufacturing operations often encounter human error, AIVIS significantly diminishes these risks. It offers real-time updates, continuous monitoring of operations, and immediate alerts when anomalies occur.

AIVIS, a sophisticated video analytical system, liberates manufacturing from the constraints of traditional management methods.

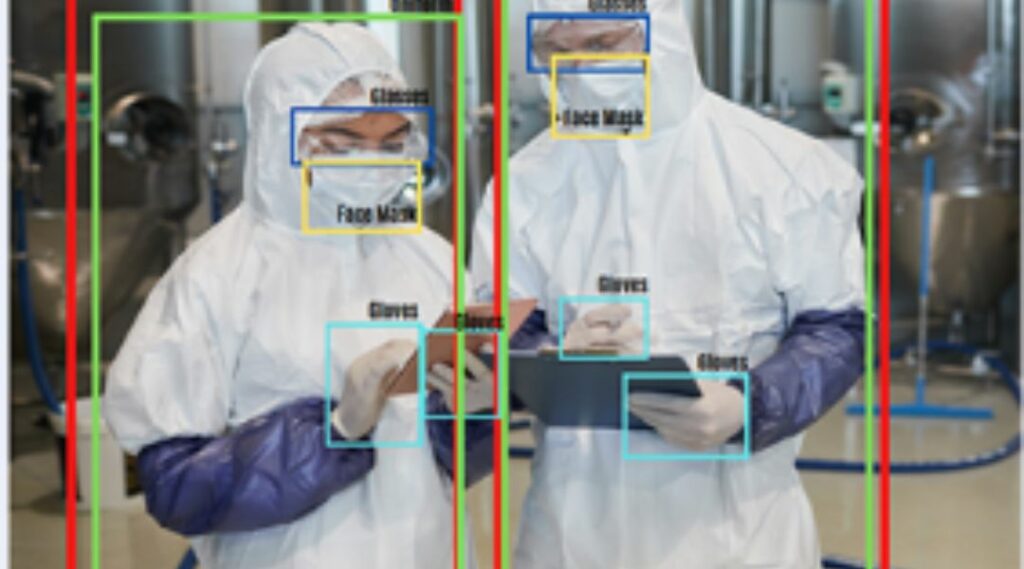

Requiring minimal supervision, AIVIS ensures the safety and security of your facility through an AI-enabled camera network.

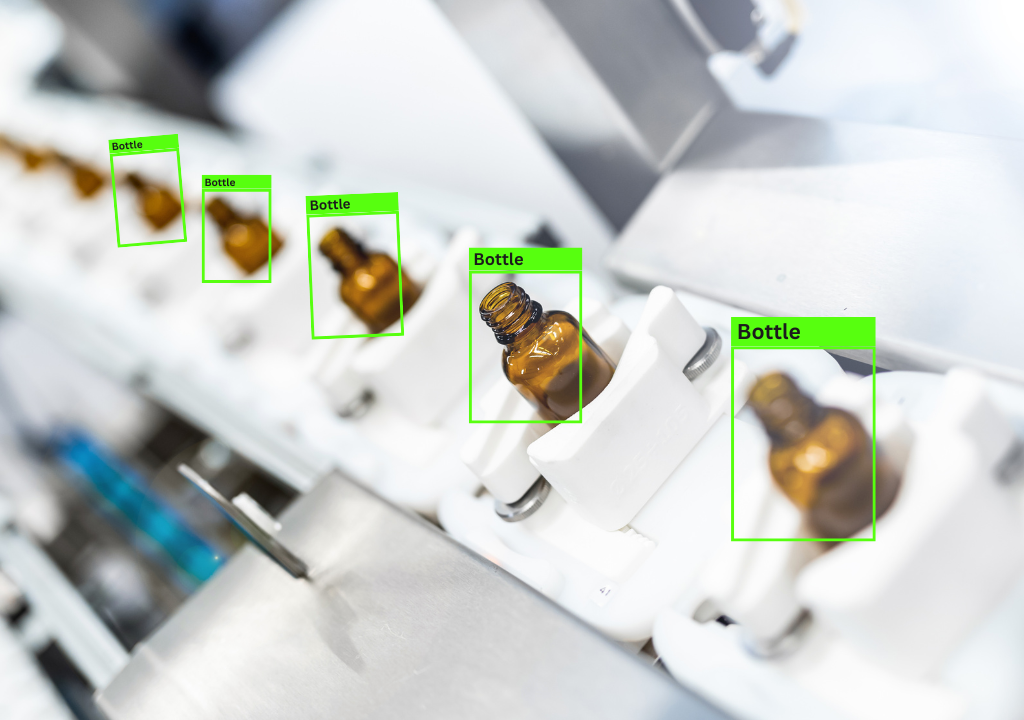

AIVIS meticulously monitors manufacturing processes, optimizing Turnaround Time (TAT) and ensuring seamless operations from start to finish. By leveraging logistics video analytics, manufacturing processes become intelligent and efficient, driven by Artificial Intelligence.

Moreover, AIVIS facilitates a reduction in last-minute losses and compliance expenses, offering an additional advantage. Monitoring TAT for parcel delivery transforms manufacturing into an automated and secure process.

This marks a departure from conventional tools, ushering in a new era of manufacturing through the integration of video analytics technology.